A Masterclass for Plastic Molding

Preparation of Raw Materials

At the heart of any successful extrusion process is the quality of raw materials. JINTU MOULD understands the importance of selecting premium polyethylene or polypropylene resins, along with appropriate additives such as antioxidants and stabilizers, which enhance the overall performance and longevity of our products.

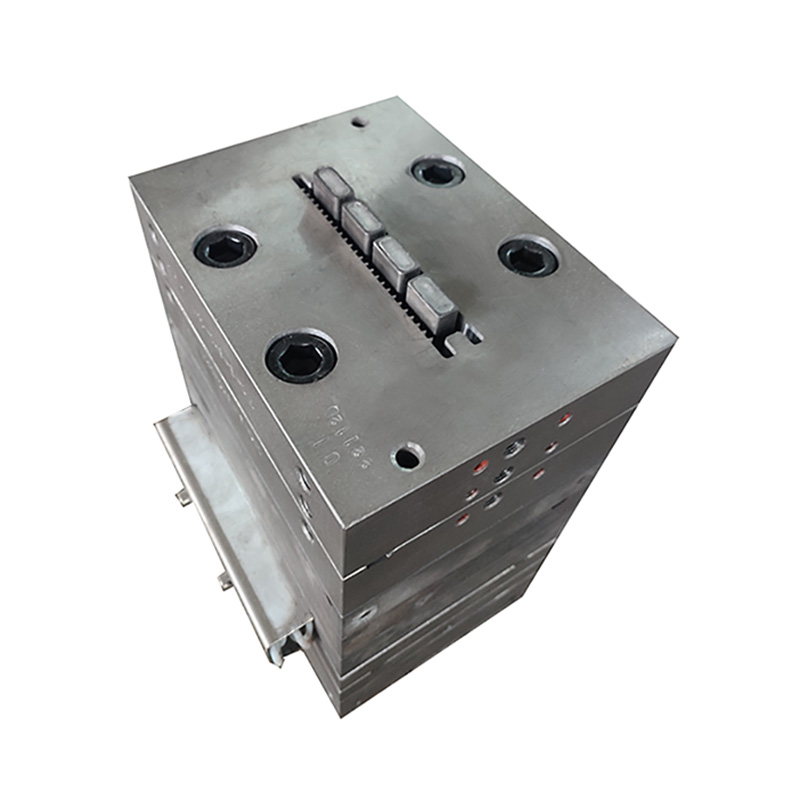

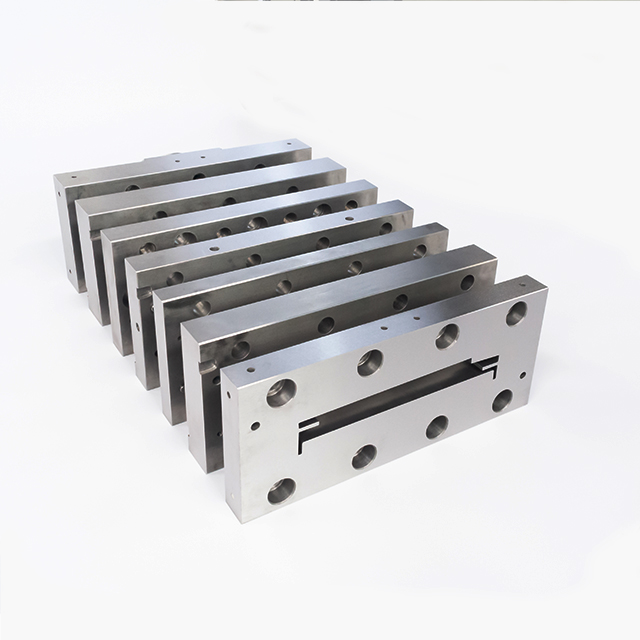

Extrusion Setup

Our engineers meticulously set up each extrusion machine according to industry standards, ensuring optimal heat transfer and material flow. From precise screw design to temperature control, every detail contributes to the seamless production line.

Extrusion Process

The core of our process lies in the extrusion step, where the molten plastic is forced through die nozzles at high speeds. This stage involves careful adjustments to achieve consistent wall thicknesses and shapes, ensuring product uniformity throughout the entire line.

Cooling and Solidification

After exiting the die, the extruded plastic is rapidly cooled down to solidify, preventing warping and maintaining its strength. We employ state-of-the-art cooling systems to ensure the material reaches its optimal condition.

Post-Processing

Finally, post-processing techniques like cutting, shaping, and finishing are applied to create the finished product. These processes ensure that the final product meets all industry standards and customer requirements.

Why Choose JINTU MOULD?

At JINTU MOULD, we prioritize innovation and efficiency, offering customizable solutions tailored to meet your specific needs. Our commitment to excellence ensures that you receive top-tier products at competitive prices, making us the go-to choice in the industry.

With our comprehensive five-step extrusion process, JINTU MOULD is dedicated to producing high-quality plastic products that meet and exceed industry standards. Whether you need a wood plastic extrusion machine or a composite profile extrusion machine, we have the expertise to deliver exceptional results. Contact us today to learn more about how we can transform your extrusion needs into a masterpiece."