What Is The Process Of Extrusion Pipe

In the world of plastic manufacturing, the process of extrusion plays a pivotal role in producing high-quality pipes and profiles. One of the most innovative solutions in this field is the 40×45L ASA PVC co-extrusion convergent line, which combines the benefits of ASA (Acrylonitrile Styrene Acrylate) and PVC (Polyvinyl Chloride) materials to create durable and versatile pipes. This article delves into the intricacies of the extrusion pipe process using this advanced technology.

What is Extrusion?

Extrusion is a manufacturing process where raw plastic material is melted and forced through a die to create a desired shape. The process is widely used in the production of pipes, tubing, and other continuous profiles. The key components of an extrusion line include the extruder, die, cooling system, and cutting or sizing equipment.

Components of the 40×45L ASA PVC Co-Extrusion Convergent Line

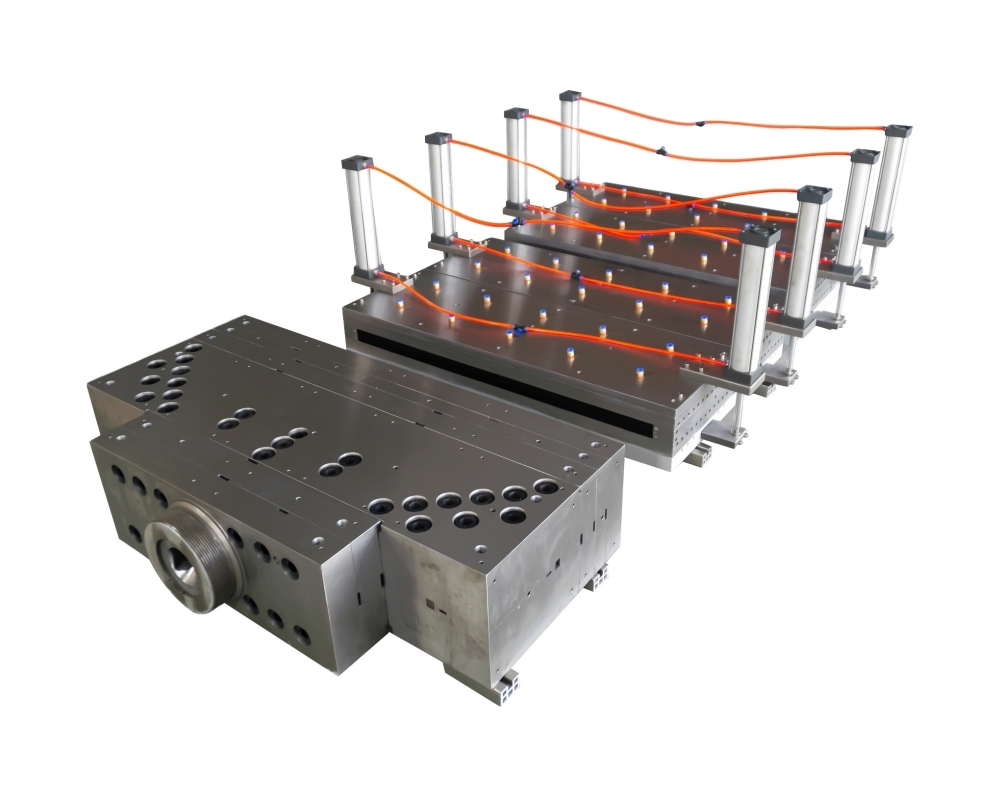

Extruder: The extruder is the heart of the extrusion process. It consists of a barrel with a screw inside that rotates to push the plastic material forward. For the 40×45L ASA PVC co-extrusion convergent line, there are typically two extruders—one for the ASA layer and one for the PVC layer. These extruders ensure that both materials are heated and mixed properly before being combined.

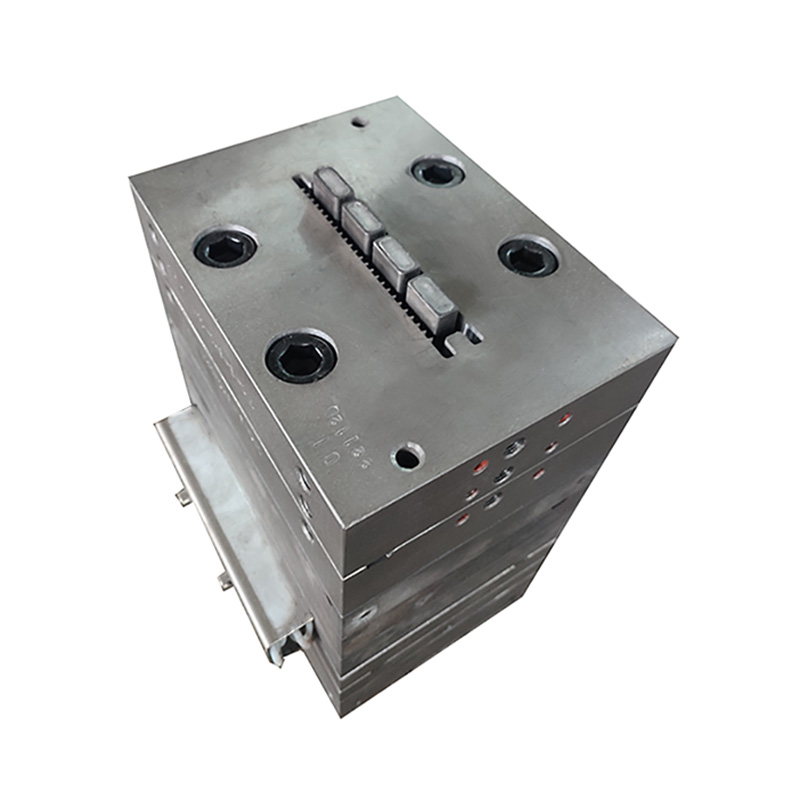

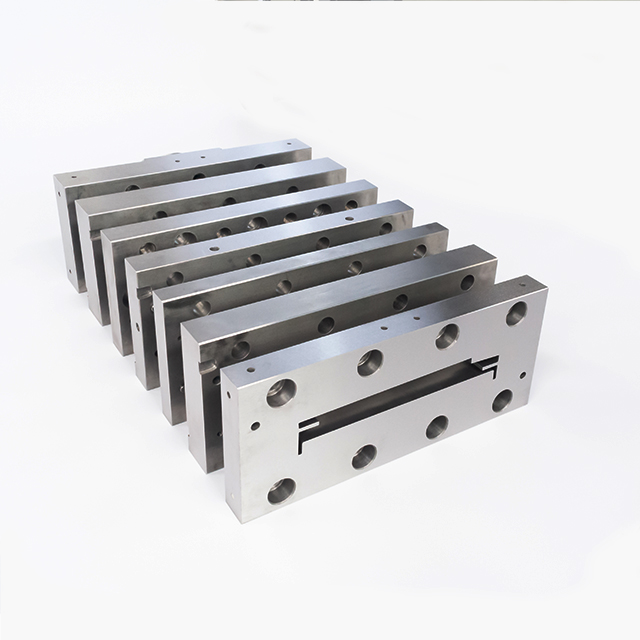

Die: The die is the component that shapes the molten plastic into the desired profile. In the case of the 40×45L ASA PVC co-extrusion convergent line, the die is designed to merge the two materials seamlessly. The die must be precisely engineered to maintain the integrity and quality of both layers.

Cooling System: After the molten plastic exits the die, it needs to be cooled to solidify the pipe. The cooling system can involve water baths, air cooling, or a combination of both. Proper cooling is crucial to ensure that the pipe maintains its shape and dimensions.

Cutting and Sizing Equipment: Once the pipe has been cooled, it is cut to the required length and sized to meet specific tolerances. This equipment ensures that the final product meets industry standards and customer specifications.

The Process of Extrusion with 40×45L ASA PVC Co-Extrusion Convergent Line

Material Preparation: The first step involves preparing the raw materials. ASA and PVC pellets are carefully measured and fed into their respective extruders. The pellets are then heated and melted by the rotating screw within the extruder.

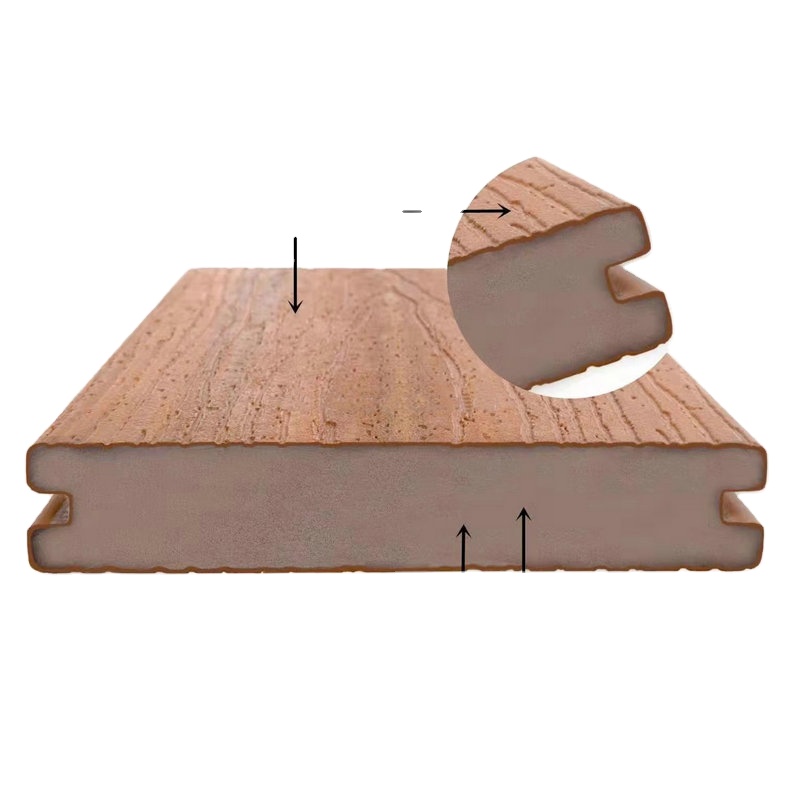

Co-Extrusion: As the molten materials exit their respective extruders, they are directed towards the co-extrusion die. The die is designed to merge the two layers of molten plastic into a single, cohesive profile. The ASA layer provides enhanced weather resistance and durability, while the PVC layer offers excellent mechanical properties and cost-effectiveness.

Shaping and Cooling: The merged material passes through the die and takes on the shape of the desired pipe. It then moves through a series of cooling stations, where it is gradually cooled to solidify. The cooling process is carefully controlled to prevent warping or deformation of the pipe.

Post-Processing: After cooling, the pipe is inspected for quality and any defects are addressed. The pipe is then cut to the required length using precision cutting equipment. Finally, it undergoes any necessary post-processing steps, such as printing, labeling, or packaging.

Benefits of Using 40×45L ASA PVC Co-Extrusion Convergent Line

Enhanced Durability: The combination of ASA and PVC materials results in pipes that are highly resistant to UV radiation, chemicals, and physical wear.

Improved Aesthetics: The co-extrusion process allows for the creation of pipes with a smooth, uniform surface and consistent color.

Cost-Effective: While ASA provides superior performance, the use of PVC in the core layer reduces overall material costs, making the final product more affordable.

Versatility: The 40×45L ASA PVC co-extrusion convergent line can produce pipes in various sizes and configurations, making it suitable for a wide range of applications, from plumbing to industrial uses.

The 40×45L ASA PVC co-extrusion convergent line represents a significant advancement in the extrusion pipe process. By combining the strengths of ASA and PVC materials, this technology produces pipes that are durable, aesthetically pleasing, and cost-effective. Whether for residential or industrial applications, the 40×45L ASA PVC co-extrusion convergent line offers a reliable and efficient solution for manufacturers looking to deliver high-quality products to the market.