WPC Extrusion Moulds & Plastic Extrusion Dies

In the ever-evolving world of manufacturing, precision and reliability are crucial, especially when it comes to producing high-quality composite materials. This is where JINTU MOULD, a leading manufacturer based in China, comes into play. Known for delivering custom solutions, JINTU MOULD specializes in the production of WPC extrusion moulds, plastic extrusion dies, composite beam moulds, and co-extrusion tools for composite columns.

WPC Extrusion Moulds: The Future of Composite Materials

Wood-plastic composite (WPC) is a material that blends the best characteristics of both wood and plastic, offering an eco-friendly solution that can be used in a variety of applications, from decking to flooring and furniture. At JINTU MOULD, we understand the need for precision and durability when it comes to creating WPC products. Our WPC extrusion moulds are custom-designed to meet the specific requirements of our clients, ensuring high-quality production processes and consistent end results.

These moulds are crafted using advanced technology to guarantee that the WPC materials are formed to the exact specifications needed. Whether you need moulds for a small batch of custom products or large-scale production, JINTU MOULD can create the ideal solution tailored to your needs.

Plastic Extrusion Dies: High-Performance Solutions for Complex Products

The world of plastic extrusion is vast, and producing plastic products with precision and consistency requires the right tooling. JINTU MOULD’s plastic extrusion dies are designed with the latest engineering techniques to ensure that plastic materials are extruded with exceptional quality and accuracy.

Our team specializes in designing custom dies that cater to specific project requirements, providing you with versatile solutions that maximize efficiency and reduce waste during production. Whether you are producing pipes, sheets, profiles, or custom plastic products, JINTU MOULD’s dies are engineered for durability, high performance, and ease of use.

Composite Beam Moulds: Reinforcing Your Structural Components

Composite beams, typically used in construction and structural applications, require advanced tooling for their production. JINTU MOULD specializes in creating custom composite beam moulds designed to handle a variety of materials such as fiberglass, carbon fiber, and other advanced composite materials.

Our custom moulds for composite beams ensure that these critical components are manufactured with precision, leading to better structural integrity, durability, and strength. By using state-of-the-art technology and materials, we can provide solutions for any beam type, from simple designs to more complex configurations.

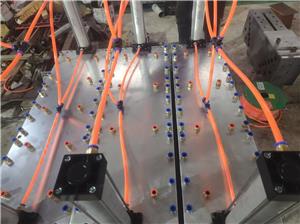

Co-Extrusion Tools for Composite Columns: Superior Multilayer Production

In many industries, the need for multicolored or multi-material composite products is growing. This is especially true for composite columns, where layers of different materials are often co-extruded to improve performance, appearance, and durability.

JINTU MOULD’s co-extrusion tools for composite columns are designed to handle these complex processes efficiently. By combining multiple materials in a single extrusion process, these tools enable manufacturers to create composite columns with enhanced properties, such as increased strength, corrosion resistance, or aesthetic appeal. With our advanced co-extrusion tools, you can achieve consistent, high-quality results across various industries.

Custom Solutions Tailored to Your Needs

One of the key aspects that sets JINTU MOULD apart is our focus on customization. We work closely with our clients to understand their specific requirements and design tooling that meets their exact needs. Whether you need a WPC extrusion mould for decking production, a plastic extrusion die for complex profiles, or a co-extrusion tool for composite columns, we ensure that our solutions are not just generic but tailored to your specifications.

Our team of engineers uses cutting-edge software and 3D modeling techniques to ensure that each tool is designed with precision before it is built. This attention to detail results in products that not only perform excellently but are also durable and cost-effective, allowing manufacturers to maximize their productivity.

Why Choose JINTU MOULD?

Expertise: With years of experience in the industry, JINTU MOULD has developed a deep understanding of the extrusion process and the challenges manufacturers face. Our expertise ensures that you get top-notch solutions.

Customization: We don’t believe in a one-size-fits-all approach. JINTU MOULD provides fully customizable solutions based on your unique needs, ensuring that every tool we produce fits your specific requirements.

Quality: At JINTU MOULD, quality is paramount. We use only the best materials and the most advanced technology to manufacture our extrusion moulds, dies, and tools, ensuring that they meet the highest industry standards.

Global Reach: While we are based in China, our products serve a global market. We have a strong reputation for delivering quality tooling to manufacturers worldwide, helping them streamline production and achieve exceptional results.

Innovation: Our commitment to innovation means we are constantly improving and adapting our designs to meet the demands of the evolving manufacturing landscape.

Whether you’re looking for WPC extrusion moulds, plastic extrusion dies, composite beam moulds, or co-extrusion tools for composite columns, JINTU MOULD is your trusted partner. As a leading manufacturer in China, we offer high-quality, custom solutions designed to meet the unique needs of your production processes. With our cutting-edge technology, expert craftsmanship, and dedication to customer satisfaction, we help manufacturers worldwide achieve their goals efficiently and effectively. Choose JINTU MOULD for all your extrusion tooling needs and experience the difference in quality and performance.