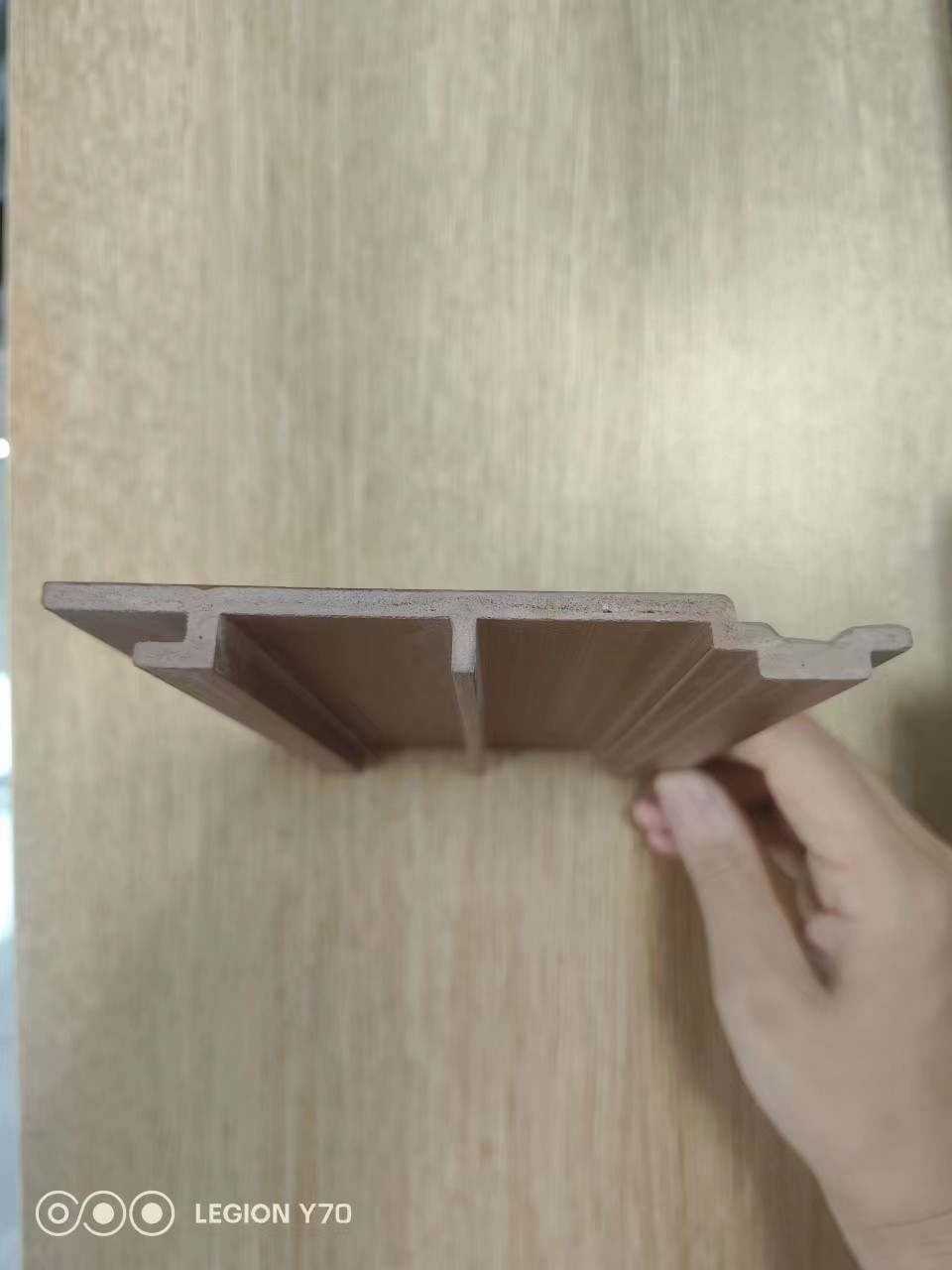

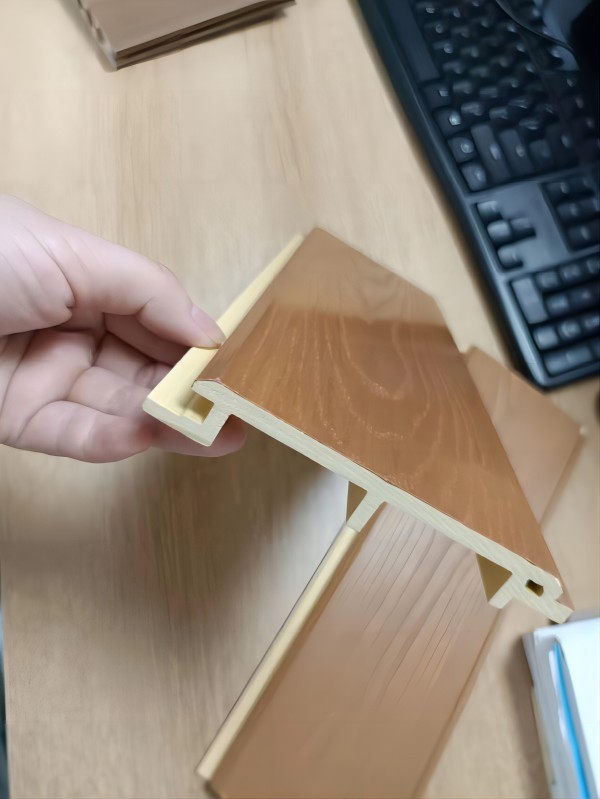

119×12 width ASA PVC external wall co-extrusion board

119×12 width ASA PVC external wall co-extrusion board

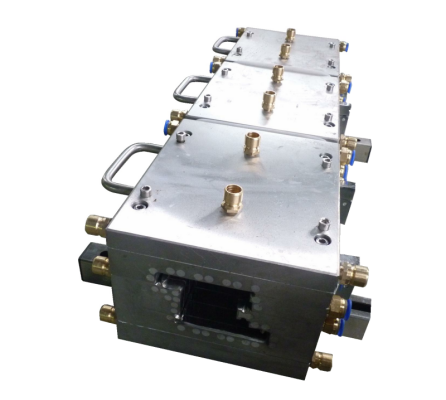

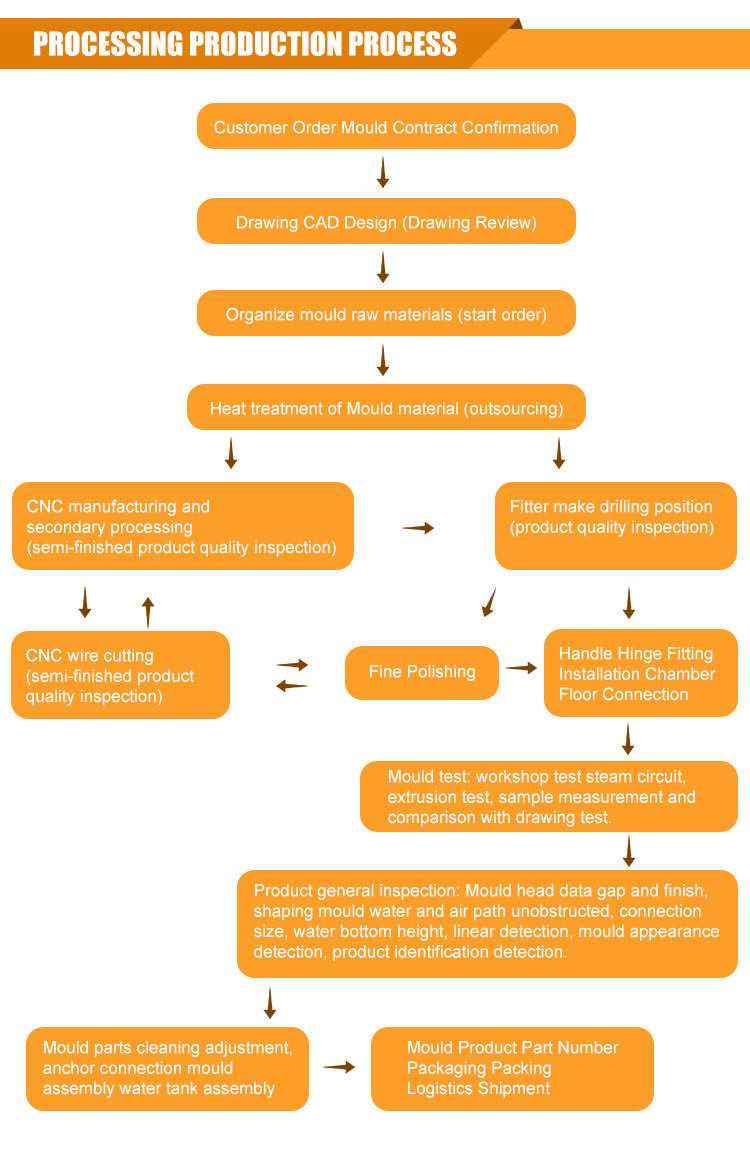

Mould Name | PVC plastic profile extrusion mould |

Mould cavity | 1 or multi-cavity |

Mould composition | Die head, aluminum heating bands, calibrators and water cooling system |

Features | Selectable co-extrusion of different raw materials: PVC/WPC/UPVC |

Selectable technology | We can provide mould with complicated profile and substance co-extrusion |

Stable | discharging, high efficiency, superior quality |

Test | Mould will be tested to get the satisfied sample before delivery Service |

Lead time | 30-40 days |

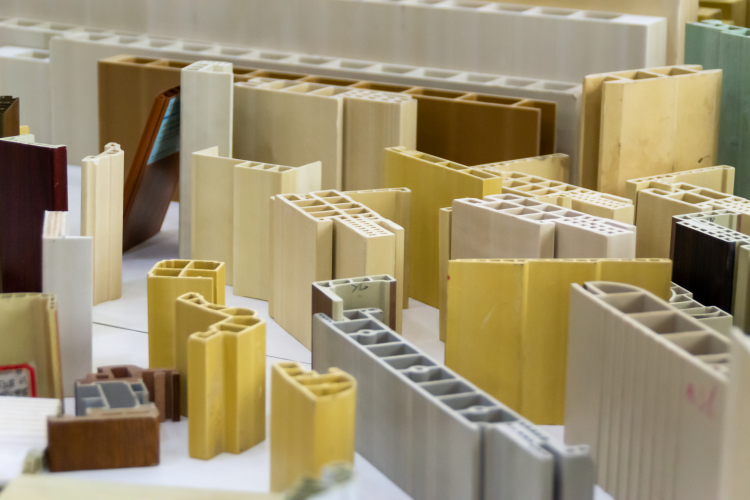

Casement door, sliding windows, shutter series,multi-cavity heat preservation multi- colour door and window series, partition wall, fence landscape, automo tive interior, electricity trunking and cable pipe series, drainage petroleum pipe line,eco--friendly and energy,saving architectural templates series. | |

Extrusion mould material | 2Cr13steel,3Cr13steel,3Cr17,D1.2316 stainless steel |

Size | Various types |

1.Use the removable positioning device ,making it easier to disassemble.2.Precise material flow control and stable extrusion.3.The hidden heating design has increased the brightness of the product surface.4.The special balance of the pressure holes has lowered the rejection rate.

1.The automatically adjusting positioning key gives it a precise size2.The tapered design of the styling sets has increased the production speed greatly.3.The inlet end is independent vacuum and shapes well.4.The camber adjusting device ensures that the line is straight.

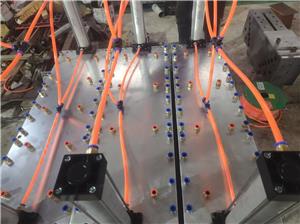

Water cooling system

1.Double vacuum system promotes the molding.

2.The combination design of eddy current and spray makes it cools fast.3.The self-adjusting water tank panels are easy to adjust.4.The stainless steel frame type system can prevent damage.5.The special influent distribution gives it a cooling balance.

Product Tag: