China Pvc Mould factory pvc profile extrusion mold

China Pvc Mould factory pvc profile extrusion mold

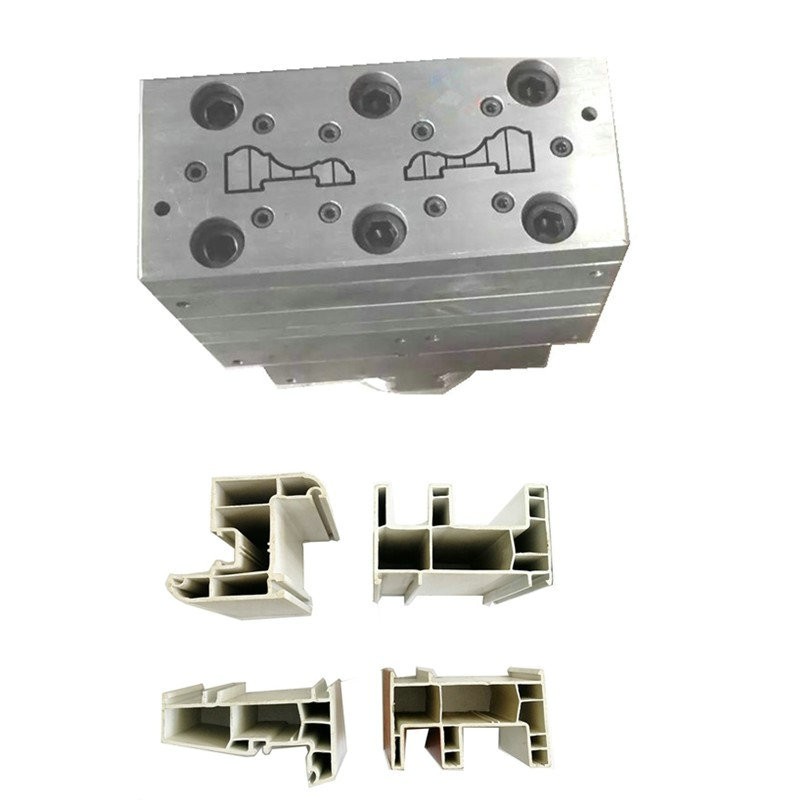

pvc profile extrusion mold

China Pvc Mould factory

pvc profile extrusion mold

Name | China Pvc Mould factory /Pvc Moulding/Pvc Extrusion Mould/pvc tools |

Size | Various Sizes as Per Customer Require |

Mould Material | 3Cr17, 3Cr17MoNiV, DIN1.2316 or Negotiable |

Mould Cavity | One or Multi-Cavity |

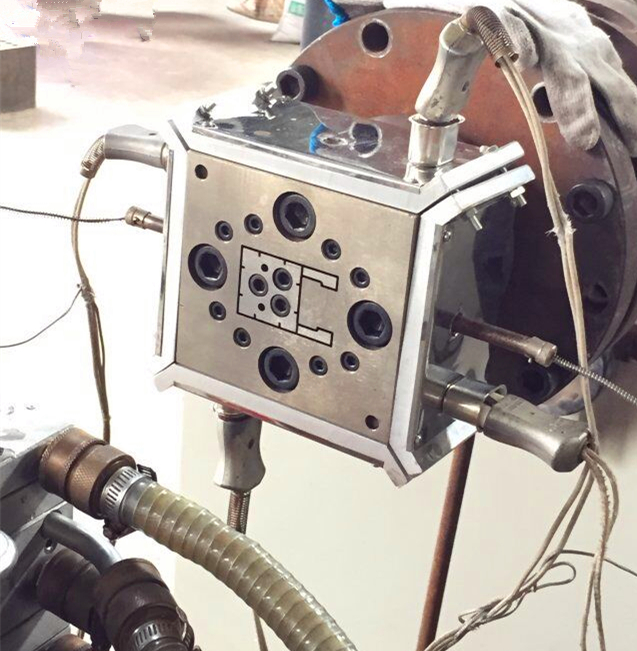

Mould Composition | Die Head, Aluminum Heating Panels, Calibrators and Water Tank |

Feature | High Polished Surface, Stable Discharging, Soft-hard, Surface Layer, Cladding |

Test | Mould will be tested to get the satisfy sample before delivery |

Sample | Sample will be arranged by express for customer approval |

Service | Provide complete set of formulation, technology and perfect after sale service |

Lead time | 30-35days |

Package & deliver | Poly wood case for exporting, each mould will be cleaned before packing. |

Remark : If you are interesting in mould and plastic prodcuts, welcome you provide us the details of the product material , size , weight ect, better 2D and 3D drawing. Welcome you to visit us. | |

mould mandrils details:

mould parts are made by HAAS CNC

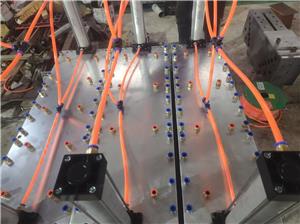

mould runner details

mould calibrators

mould water tank

Plastic Extrusion Mould Production Flow

Question 1,May I know what contains for one set of mould?

Answer1: As usual,one set of mould include Die Head, Aluminum Heating Panels, Calibrators and Water Tank.Final configuration will be confirmed according to your profile drawing.

Question 2,May I know could you do the mould testing for us when it finished?

Answer2: Of course,we have 2 sets of extruder lines for moulds testing.

Question 3,May I know your moulds can euipped with our extruder lines?

Answer3: Sure,we will design the moulds according to your extruder adapter.However,you should send your machinery adapter for us firstly before moulds designing.Also,we will send our technical form to you to fill the information we request.

Question 4,May I know one mould can make all kinds of profile ?

Answer4: Sorry,one mould can only make one kind of profile,one shape one mould.

Question 5,May I know what's the cooling style of your mould?

Answer5: Our WPC extrusion mould is water cooling not air cooling,water cooling can improve the output speed and make the product rapid successful shape coming out .

It is very easy to test because of our 500 sets/year WPC moulds designing,making and testing rich experiences.We know the WPC material flow ,we know how to control the dies compression ratio,we know the best cooling style.Using our mould will save moulds testing material,save electrical power,save labour.Our mould will make the perfect sample for the first testing.

1,Over the past decade,we always provide customers with perfect service.

2,Our technicist will test each mould before they leave the factory according to our customer request.

3,We could give the whole support for customer in raw material formula,selection of extruder machine,mould technique and operation training on the spot.

4,We also can supply top-quality moulds and resonable price depends on customers requests(pictures or CAD drawing or samples).We also provide OEM service