plastic extrusion machine production Line / wood plastic extrusion machine / composite profile extrusion machine

hot sale plastic Extrusion machine Production Line / wood plastic extrusion machine / WPC profile extruder

65/132 conical twin screw extruder line

Summary

Service conditions: 380V / three-phase / 50Hz

1000mm Center height: 1000mm

Equipment Color: company standard color (red, white)

Equipment includes

PE wood plastic screw feeder (1 set)

Sjz65 / 132 conical twin screw extruder (1 set)

Yf300 type calibration table (1 set)

Haul off unit ( 1set )

Cutting machine (1 set )

Stacker (1 set )

1,Equipment configuration

PE wood plastic screw feeder

1000kg/h Feeding capacity: 1000kg / h

1.5KW Motor power: 1.5kw

104 Suction pipe diameter 104

Advantages: convenient operation, simple maintenance, overload protection, automatic detection, automatic feeding.

2,Sjz65 / 132 conical twin screw extruder

Design output of extruder: 200-

The amount of extrusion depends on

the processing materials and

operating conditions.

There may be corresponding changes.

(design output)

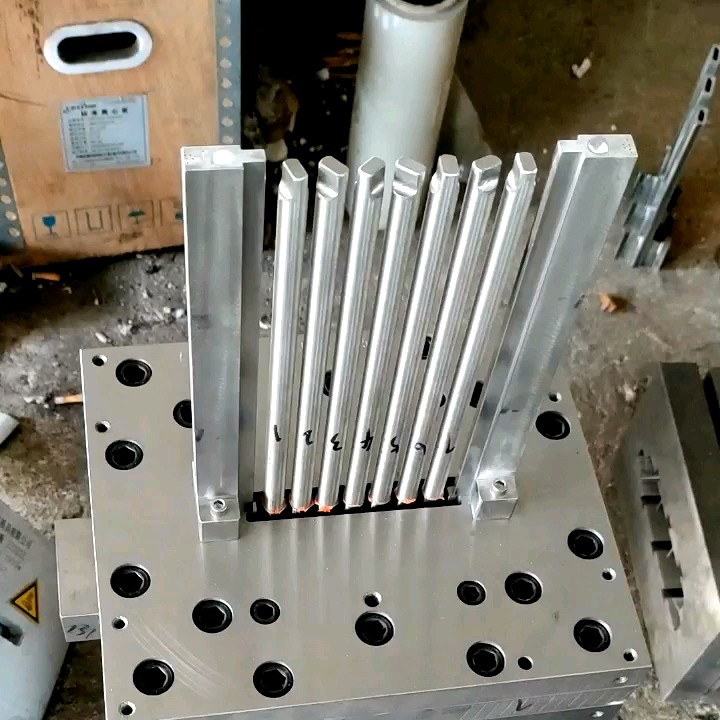

——Specification of screw and barrel: screw and barrel material:38CrMoAl a forgings. Nitriding treatment (HV)850-960, brittle grade I, nitriding layer depth 0.6-0.8mm. (special barrel and screw for wood plastic material)

crew diameter: 65 / 132mm

Length: 1380mm

Number of screws: 2

Heating section number and power of barrel: 5 sections, about 22KW. Temperature control range (including core flow) is 50-300 ℃. 5 heating Number of cooling sections of barrel: 3; fan cooling.

.Electrical control and temperature control part: Schneider contactor, Omron temperature meter, Delixi for air switch, etc.

Main drive motor power: 37KW (AC)

Transmission and reduction system: adopt the combination form of hard tooth surface and oblique tooth surface, and gear carburizing and grinding.

Gearbox: the latest type, high torque, low noise, vertical box. The gearbox has the advantages of low maintenance cost and strong resistance to use.

Gearbox cooling medium: water

Quantitative feeding system: adopt single screw automatic forced feeding.

0.75KW.Power of forced feeding motor: 0.75KW.

3KW Vacuum pump motor: 3kw

Connection mode of extruder and die: transition connection of confluent core. (flange fixed)

Vacuum barrel: external type, easy to clean and maintain.

:3200mm×1550mm×2450mm Overall dimension: 3200mm × 1550mm × 2450mm

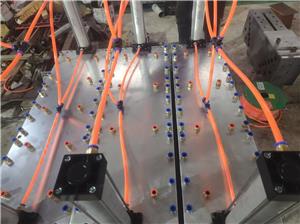

3, Calibration table

Product size: (can be customized according to customer needs)

Length of calibration table: 4m

Main material: 304 stainless steel

1100mm calibration table width: 1100mm

—— Cooling water connector: 20 pieces in total

—— Water tank material: 304 stainless steel

——1.1KW Power of vortex air pump: 1.1kw

——Vortex air pump: used to blow water on the plate area (equipped with four blowpipes)

—— Mould installation guide rail: high quality aluminum alloy with T-groove profile

——60mm Mould installation center distance: 360mm

——Front and rear moving power and range: adopt 0.75KW cycloid pinwheel reducer for adjustment, with the adjustment distance of 800mm;

——The motor turbine control setting table moves back and forth quickly and adjusts up and down positions.

——Electric lift, lead screw lift.

——The horizontal left and right position of aluminum guide rail can be adjusted manually.

——Built in mobile guide with travel protection switch.

——4050mm×1030mm×1000mm Overall dimension: 4050mm × 1030mm × 1000mm

4,Cutting machine

——Product size: 300 × 100mm (can be customized according to customer demand)

——Cutting method: transverse cutting

——Cutting motor power: 2.2kW (special motor for wood plastic profile)

—— Saw blade: 450mm; high quality alloy steel material, suitable for Cutting of PE wood plastic products

—— Saw blade speed: 2800 rpm

——Cutting and pressing device: pneumatic, up and down automatic pressing

——The saw blade cover is equipped with a dust proof curtain strip.

——Imported guide wheel

——Install toughened glass protective cover.

——The bottom of the cutting machine is equipped with a dust storage box, which is used for the collection of sawdust and can ensure the clean reuse of sawdust.

6,Stacker

——Length: 6M

—— Stainless steel bracket structure is adopted,

——Fixed length: fixed length cutting mode of proximity switch

——Discharge: pneumatic automatic discharge, saving time and labor.